expand your capabilities

cost effective manufacturing

automation solutions

Cost-effective manufacturing automation solutions are paramount in today's competitive industrial landscape. Modular and scalable systems is a cost-effective way to increase capabilities while retaining flexibility and growth without significant reinvestment. They are typically quicker to implement, quicker to breakeven, and has lower financial and operational risk over larger integrated systems.

6 months

target to breakeven on investment

900%

increase in ppm over manual inspection

20 years

mfg optimization and automation

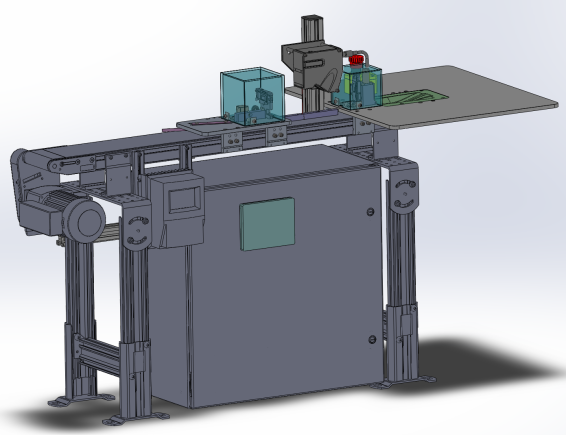

60 PPM automated LFA device inspection

Conveyor-based LFA test strip insepction for devices that are in or out of their housings. 60 PPM.

30 PPM automated LFA device inspection

Coming soon: Benchtop LFA test strip insepction for devices that are in or out of their housings. 60 PPM.

automated LFA membrane treatment with inspection

Coming soon: Benchtop LFA test strip insepction for devices that are in or out of their housings. 60 PPM.

automated equipment design

We design and integrate custom automated and semi-automated equipment into your production lines. typical requests are to customize or improve on existing equipment or design equipment from the ground up.

equipment validation

We use our expertise in drafting and performing FATs SATs, IQs, OQs, and PQs. This means that your investment into your new process or equipment will work the way it was intended.

NPI

With our expertise with NPI, we transfer product designs to manufacturing by providing comprehensive support in setting up pilot production programs.

DOE/performance characterization

We use a systematic approach to characterize your equipment. These tests mitigate risks to confidently launch a consistent and reliable production process.

engineering and project management

Cross-functional projects require coordination throughout product development and launch. Effective project management means that your project complies to regulatory, safety, and quality standards.

manufacturing and sustained engineering

Manufacturing and sustained engineering ensures streamlined production. The duality of recommending cost-down opportunities and minimizing down time keeps our clients' production running as best as possible.

design principles

assess

Each unique situation is assessed to clearly and accurately define the potential for improvements in operational capabilities. Tools like gap analyses are often used to uncover the true needs.

solve

Cost-effective solutions are often based on the available budget. We tailor our solutions to meet budgetary goals. This means that capital can be invested into multiple projects to get more impact with your investment.

implement

The final step is to make the solution work. Throughout the typical phases of assembly, debug, characterization, and validation, the goal is to have a intervention-free solution in your production so that you can focus on profitability.